|

|

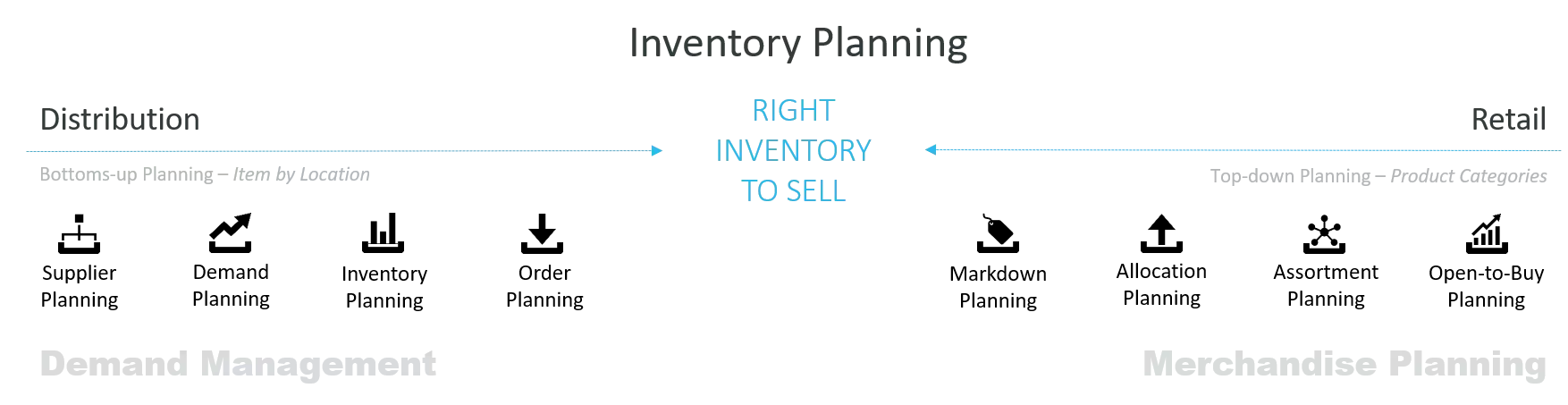

WHAT IS THE GOAL OF INVENTORY PLANNING?

|

|

Getting the right inventory to the right spot at the right time for the right price is inventory planning.

Inventory challenges can come in many forms for both retailers and distributors. In fact, both worlds are colliding with the emergence of e-commerce. Knowing all the aspects of inventory planning is critical to addressing all of your inventory and software challenges.

Distributors

|

Retailers

|

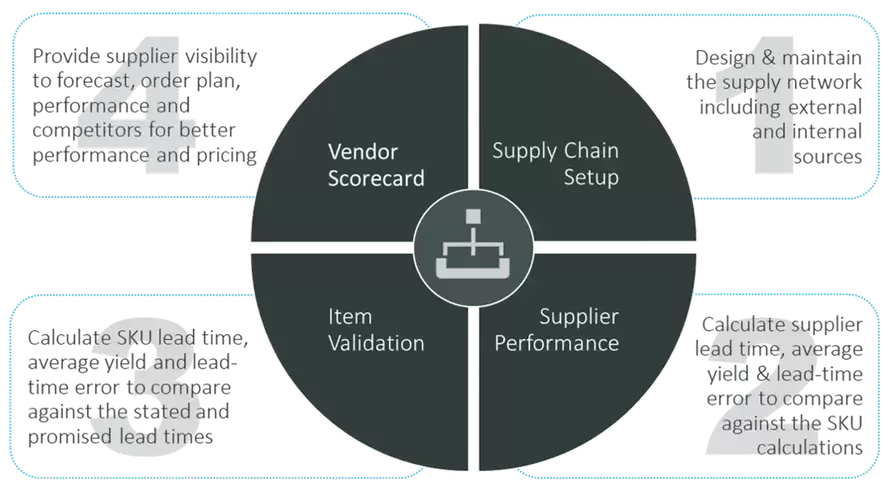

Supplier Planning

Do your suppliers always deliver on time with the right amount?

Supplier Planning provides the ability to monitor supplier performance and incorporate supply variability into the planning process. It is often the most overlooked aspect of planning even though it is the most important. Accurate lead times are essential for calculating accurate forecasts, safety stock, cycle stock and orders. Start managing your suppliers so they are not managing you.

MANAGE YOUR SUPPLIERS AND OPTIMIZE YOUR SOURCING

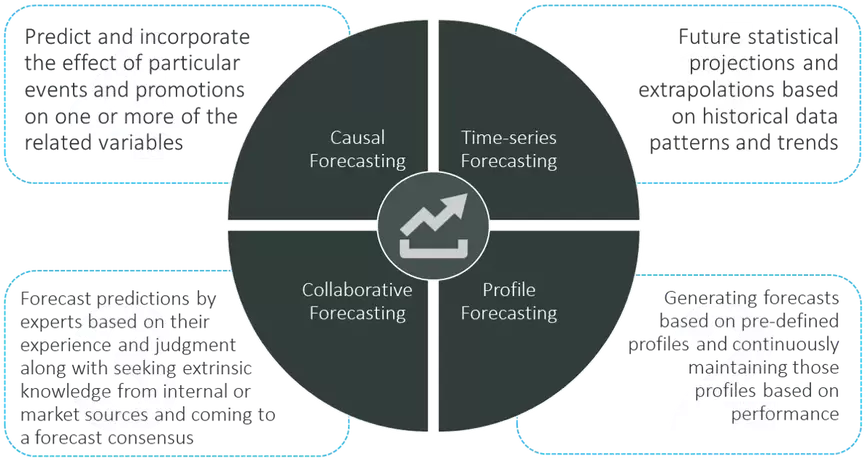

Demand Planning

We know your forecasts are wrong but how wrong are they?

Demand Planning and forecasting remain the cornerstone of every good plan. It is among the most impactful and recognized planning tool as it is often referenced throughout any organization as it relates to having the right inventory and orders. But, what matters most is knowing how wrong the forecast is and how to manage it.

PLAN TO MORE ACCURATE FORECASTS

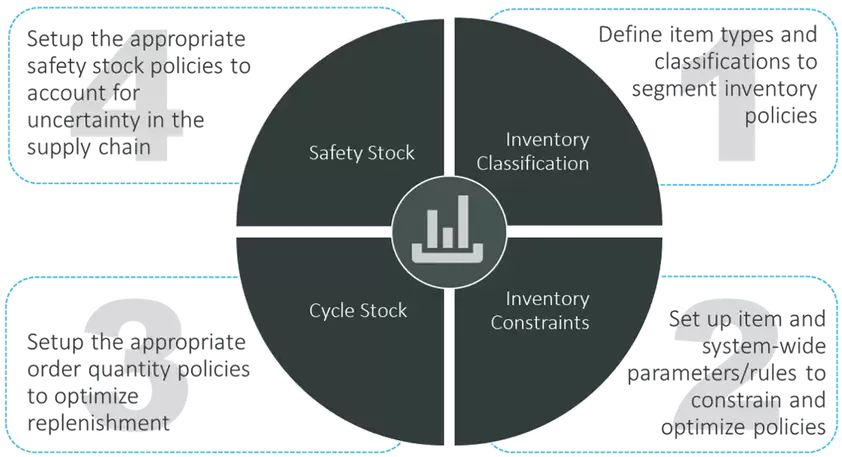

Inventory Planning

Are your service level expectations aligned with your inventory goals?

Inventory Planning provides you with a target and a projection of how much inventory you should stock based on what service you want to provide to your customers. Understanding the balance and relationship between customer service and inventory is critical to optimizing the inventory throughout your distribution network.

BALANCE CUSTOMER SERVICE WITH INVENTORY INVESTMENT

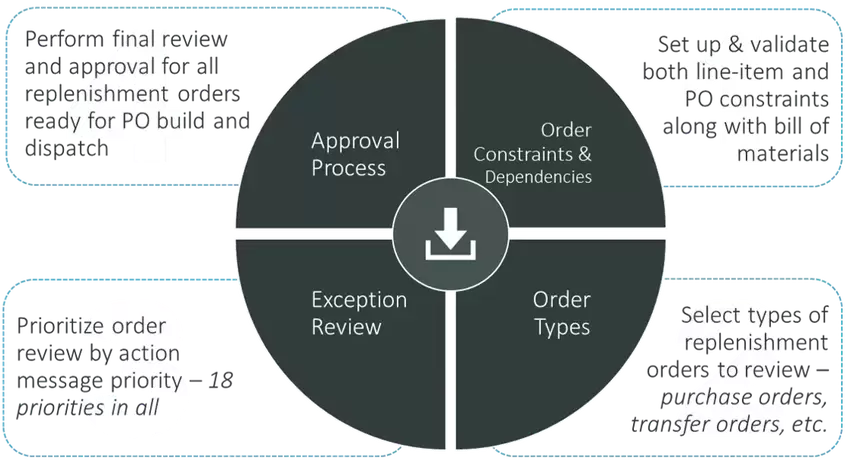

Order Planning

Do you really know when to place and receive your orders?

Order Planning is ensuring your products are at the right place at the right time - simple right? It is if you have taken the steps to monitor, manage and incorporate all the elements of supplier, demand and inventory planning along with those that influence replenishment such as ordering constraints and dependencies.

PLACE ORDERS AT THE RIGHT TIME FOR THE RIGHT QUANTITY

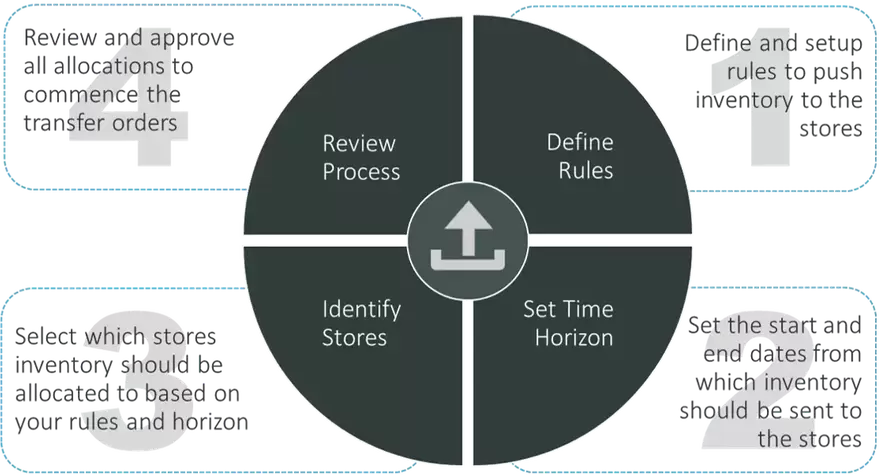

Allocation Planning

Do you know how much inventory to send to your stores?

Allocation Planning is the ability to push inventory to your stores based on product or business rules. When you have inventory that you want to sell, you need to allocate that inventory to your stores so you can sell it quickly and at higher margins. Limit the amount of inventory that you send to stores that won't sell based on expectations.

PUSH INVENTORY TO THE STORES THAT WILL SELL FAST FOR HIGHER MARGINS

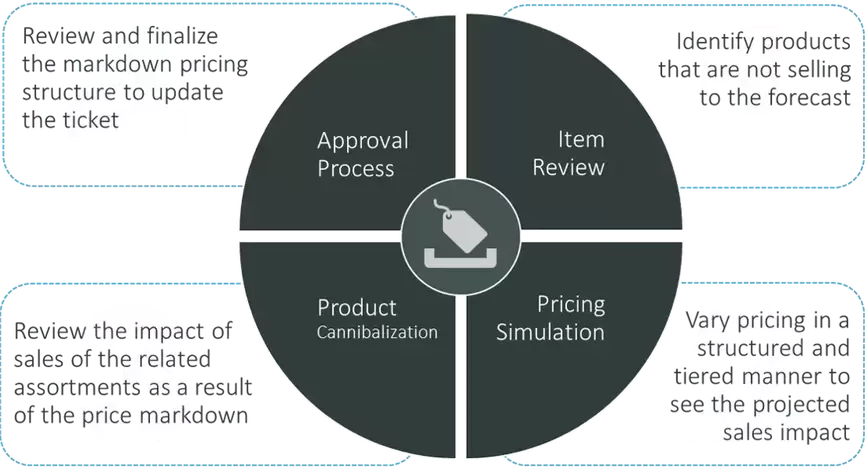

Markdown Planning

Are you reducing your prices too much and too quickly?

Markdown Planning helps you understand the relationship between demand and price. Knowing how price will affect your demand, is critical for maintaining inventory levels and managing sales. Similarly, understanding how demand changes could impact your prices helps you optimize your margin.

PLAY WITH PRICING TO SEE HOW IT DRIVES DEMAND

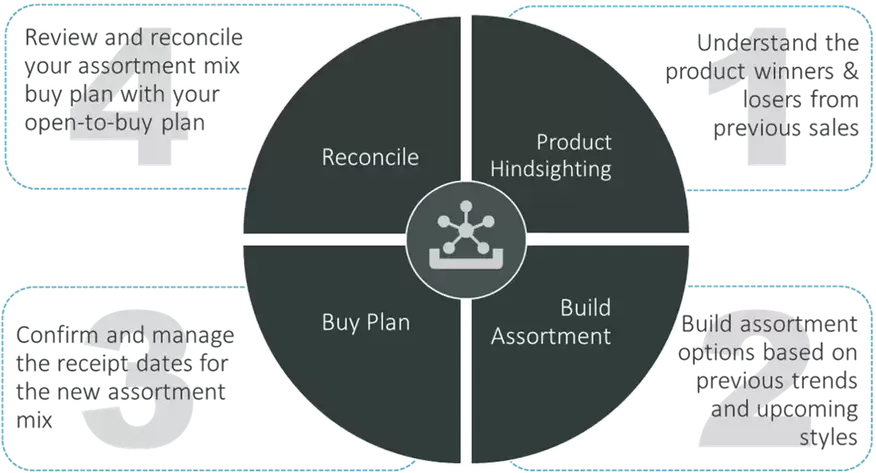

Assortment Planning

What products should you offer to your customers?

Assortments are the foundation to planning your product mix for the season. It is important that your product mix aligns with your financials goals. You also want to limit the number of new products to the market that won't sell. Incorporate the seasons sizes and colors that are trending to sell best.

MAKE SURE YOUR PRODUCT MIX IS WHAT THE CUSTOMER WANTS

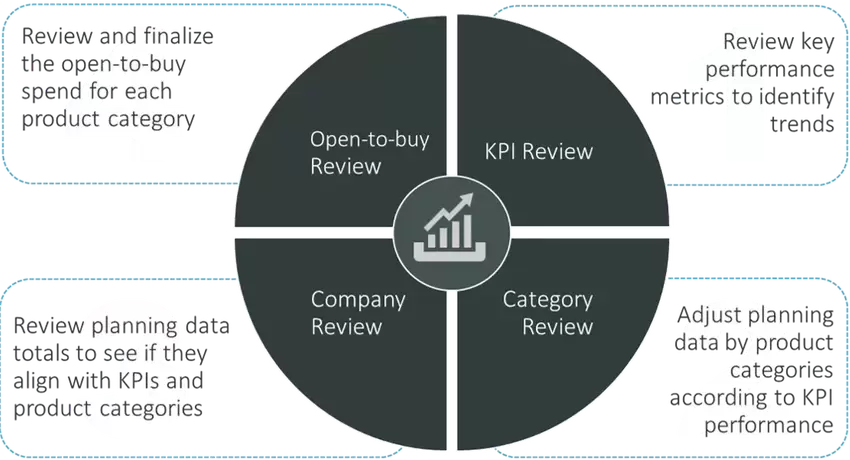

Open-To-Buy Planning

Do you know how much money you can spend to purchase product?

Open-to-buy planning gives you insight to what your spend should be to purchase more product, while balancing your inventory, orders, forecast and assortment. Navigating your spend by your product hierarchy will allow you to better manage your budget so you maintain a positive cash flow.

START PLANNING YOUR SPEND, SALES, INVENTORY AND ORDERS

|

|

HOW DO THE DIFFERENT PLANNING ACTIVITIES INTERACT?

|

|

Are you reconciling your bottoms-up and top-down plans?

Whether you are a distributor planning at the item by location level or a retailer planning at the various levels of your product hierarchy, you are ultimately building a plan to place orders so you have inventory from which you fulfill demand. All planning activities have a key role in fulfilling this one goal. Making sure each role is being fulfilled and reconciled is the challenge most planners face.