Understanding the importance of lead-time accuracy is crucial to your inventory plan.

Is Lead Time Accuracy Really Important?

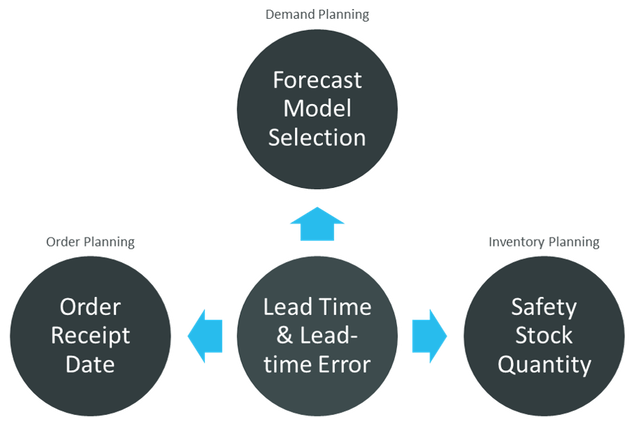

YES!!! Lead time might be one of the most important and influential inputs to your planning software. It still amazes me how often companies will use stated lead times and not validate or calculate the true/actual lead time. Poor lead times will impact and degrade your forecasting, safety and cycle stock calculation, and order plan.

How does lead time impact your forecasting? Perhaps the most overlooked consequence, best of breed software solutions will calculate and use lead-time forecast error. The lead-time forecast error will influence which forecast model is selected in traditional statistical forecasting engines. If your lead time is not accurate, your forecast engine may not be selecting the best forecast model in its simulation or tournament of best fit since the forecast error over lead time may be unreliable. After all, planners should be most concerned with the lead-time forecast when reviewing monthly or weekly forecasts.

How does lead time impact your forecasting? Perhaps the most overlooked consequence, best of breed software solutions will calculate and use lead-time forecast error. The lead-time forecast error will influence which forecast model is selected in traditional statistical forecasting engines. If your lead time is not accurate, your forecast engine may not be selecting the best forecast model in its simulation or tournament of best fit since the forecast error over lead time may be unreliable. After all, planners should be most concerned with the lead-time forecast when reviewing monthly or weekly forecasts.

How does lead time impact your safety and cycle stock calculation? There are numerous ways to calculate safety and/or cycle stock. When optimizing your safety stock based on a service level objective, not only is the forecast and forecast error considered, but so is lead time and lead-time error. The longer the lead time and the larger the lead time variance, the more safety stock you need, and vice versa. If you are trying to minimize your total annual costs by using the economic order quantity (EOQ) to define your cycle stock (1/2 EOQ), the EOQ is directly proportional to the forecast, which as described above, could be unreliable as the forecast selection is dependent upon the forecast error over lead time.

How does lead time impact your order plan? This may be the most obvious system calculation impacted by poor lead times. And, generally it is the order plan that planners will focus on when validating the accuracy of the supplier stated lead time . Having inaccurate lead times could either generate orders too earlier or not early enough resulting in over stock and under stock situations, respectively.

Having a system calculate and manage (1.) lead time along with (2.) an estimate of how wrong your lead time may be is critical to optimizing all functions of your planning software.

Are you taking into account supplier lead-time variability when replenishing?

Contact us and let us know if there is anything you would like us to write about as we are always looking for exciting new supplier and lead-time software topics for our readers.