Check out our latest article how to optimize your inventory.

Inventory Optimization & Strategy

A core competency of any inventory planning system is inventory optimization and strategy. Despite inventory optimization being the primary influence to your return on investment of the system, most planners do not proactively manage their inventory strategies. Consider that your inventory planning software is a complex mathematical engine designed to manage the errors throughout your supply chain, managing your inventory optimization and strategy is essential to understanding what that error is costing you, in both dollars and service. Nevertheless, inventory planning is still overlooked as a value added task and process which planners should add to their workflow schedule.

What is Inventory Optimization and Strategy?

Everyone knows how important inventory is to distributors and retailers – no inventory, no sales. Inventory optimization and strategy is a set of rules you apply to your items that will minimize the amount of inventory you need to provide the customer service you want and can afford.

Every company would like to fulfill all customer orders all the time but the cost to do so is too high based on the inventory investment required, especially for low volume, highly volatile items. Inventory optimization balances the cost of inventory against desired service levels to maximize your profit. Your inventory plan and strategy addresses how you apply and manage that balance across your stocked items. The two most important drivers of your inventory optimization and strategy is your cycle stock optimization and your safety stock optimization.

What is Cycle Stock Optimization?

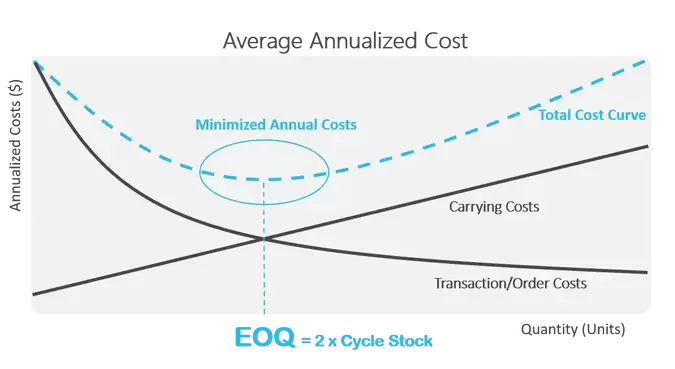

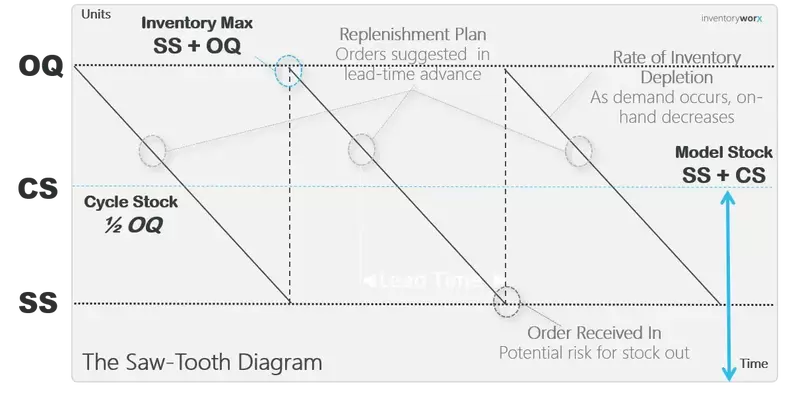

Cycle stock optimization is how you set your item-level ordering quantities based on the costs of holding your forecasted inventory versus the transaction costs of ordering and receiving it. The economic ordering quantity formula is a well-known model of cycle stock strategy that considers some of these cost trade-offs. Your cycle stock represents half of your ordering quantity. Cycle stock, however, is often driven by minimums and multiples like case pack quantities. Cycle stock optimization considers forecast, numerous carrying and ordering costs and any line-item ordering constraints. Generally, your cycle stock strategy makes up most of the inventory you have stocked which is why it is important to manage in your inventory optimization and strategy policies. By planning and optimizing your cycle stock, you can achieve significant service levels without holding any safety stock.

What is Inventory Optimization and Strategy?

Everyone knows how important inventory is to distributors and retailers – no inventory, no sales. Inventory optimization and strategy is a set of rules you apply to your items that will minimize the amount of inventory you need to provide the customer service you want and can afford.

Every company would like to fulfill all customer orders all the time but the cost to do so is too high based on the inventory investment required, especially for low volume, highly volatile items. Inventory optimization balances the cost of inventory against desired service levels to maximize your profit. Your inventory plan and strategy addresses how you apply and manage that balance across your stocked items. The two most important drivers of your inventory optimization and strategy is your cycle stock optimization and your safety stock optimization.

What is Cycle Stock Optimization?

Cycle stock optimization is how you set your item-level ordering quantities based on the costs of holding your forecasted inventory versus the transaction costs of ordering and receiving it. The economic ordering quantity formula is a well-known model of cycle stock strategy that considers some of these cost trade-offs. Your cycle stock represents half of your ordering quantity. Cycle stock, however, is often driven by minimums and multiples like case pack quantities. Cycle stock optimization considers forecast, numerous carrying and ordering costs and any line-item ordering constraints. Generally, your cycle stock strategy makes up most of the inventory you have stocked which is why it is important to manage in your inventory optimization and strategy policies. By planning and optimizing your cycle stock, you can achieve significant service levels without holding any safety stock.

What is Safety Stock Optimization?

Where cycle cost optimization is mostly cost driven, safety stock optimization is service driven. Optimizing your safety stock strategy is generally perceived as inventory optimization despite it being the smaller aspect of the two key components. Key factors considered in safety stock optimization are your service level targets, your forecast, how wrong your forecast might be, your lead time and how wrong your lead time might be. Lastly, a key consideration in safety stock optimization is the amount of service your cycle stock will provide with no safety stock.

Traditional safety stock methods such as a fixed safety stock, days of supply or forecast, or even simpler service-level methods do not consider all these factors. Safety stock strategies should, however, vary across all your items as there is never one answer for all items. Stratifying your safety stock policies by ABC classification is a great way to approach your inventory optimization and strategy.

Every stocked item will be subject to your inventory optimization and strategy such that you can map your “sawtooth” diagram to understand your past, current, and future investment. By applying cycle stock optimization and safety stock optimization you will optimize your inventory investment while achieving desired services levels. After all, your inventory investment for a single item or for all items is simply your safety stock plus your cycle stock – an easy way to model your future inventory investment.

Do you know what your true, no-expediting, on-time delivery, 100%-fulfillment service level is?

Contact us and let us know if there is anything you would like us to write about as we are always looking for exciting new inventory optimization topics for our readers.